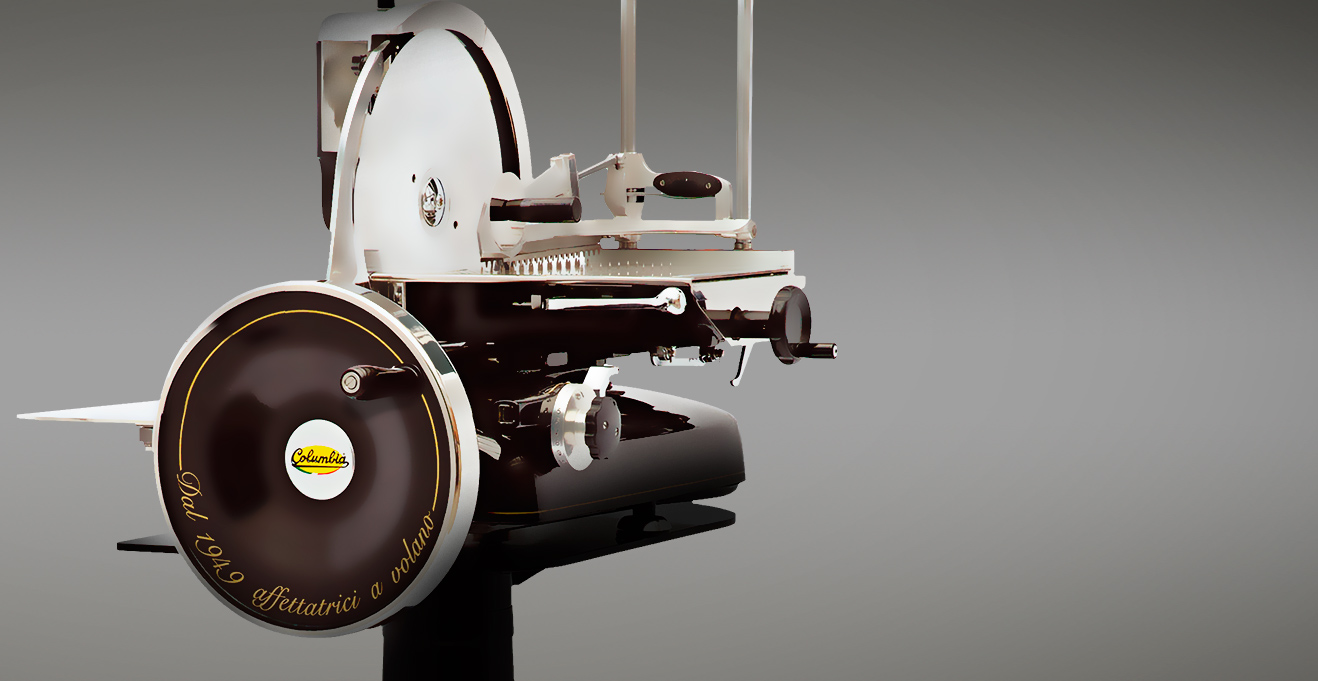

Columbia slicing machine:

the importance of the flywheel.

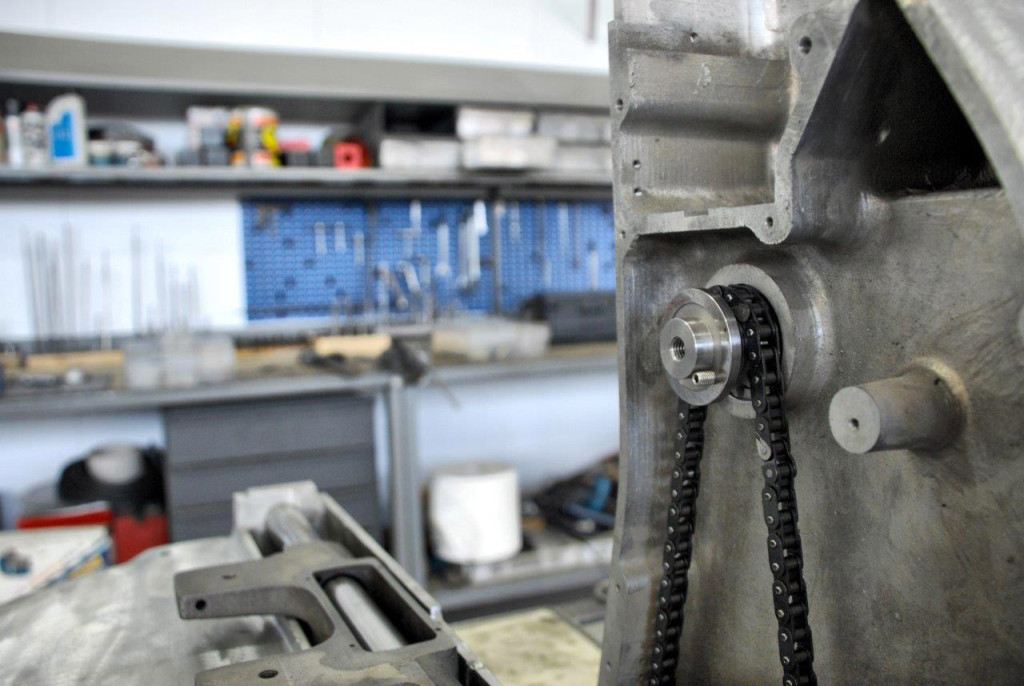

The cut of a flywheel slicing machine is comparable to a cutting knife.

The speed of the carriage, by the flywheel, depends on an active intervention of the operator. In addition a system of cut through a fixed and mechanic product movement to the blade obtaining slices up to 0,3 mm thickness.

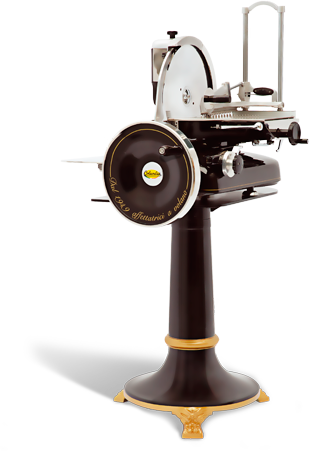

Classic models.

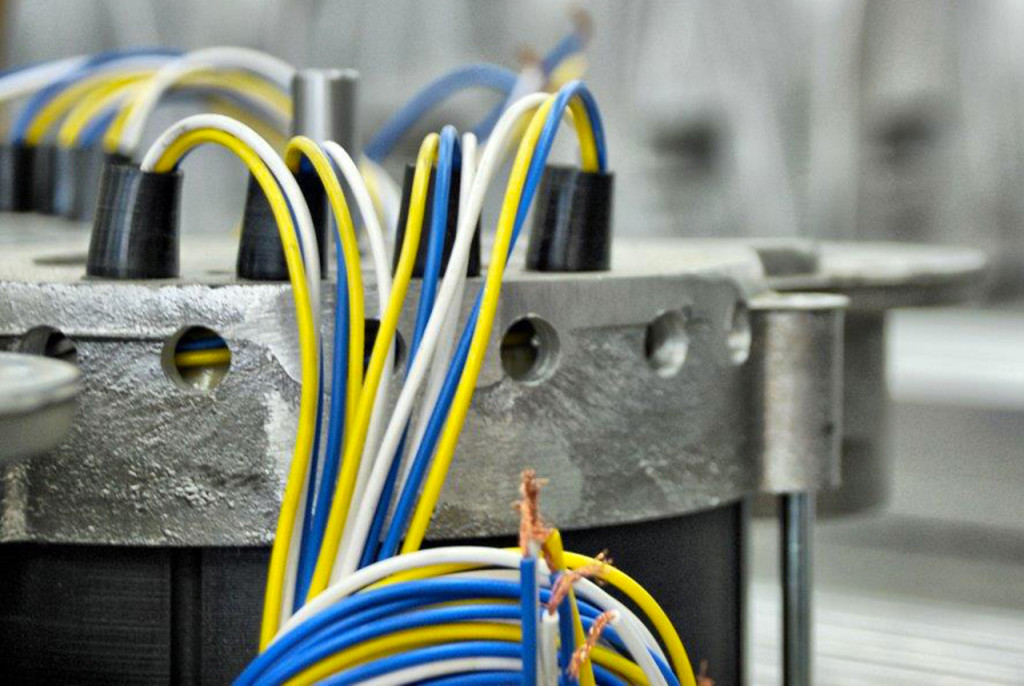

Columbia are professional slicing machine with flywheel and 370 mm blade made for universal cutting. The range includes one manual and one semi automatic model. Made by an aluminium body, the flywheel and the stand (optional) in cast iron, with all the surfaces that are exposed to the food products made from stainless steel and a special steel “Durochrom” blade which guarantees very precise and perfect slicing.2002 Manual model

Blade dimension: diameter 370 mmPerimeter dimensions: diameter 100 cm

Max height distance: 67 cm

Maximum cut capacity: 220 mm

Carriage stroke: 315 mm

Slicers weight: 95 kg

Metal pole weight: 85 kg

Blade turns: 1 flywheel turn = 3 blade turns

2002-2V

Semi automatic

Blade dimension: diameter 370 mm

Perimeter dimensions: diameter 100 cm

Max height distance: 67 cm

Maximum cut capacity: 220 mm

Carriage stroke: 315 mm

Slicers weight: 120 kg

Metal pole weight: 85 kg

Feed tension: 380V 50 Hz

Motor blade and carriage: 500W

Motor speed: first speed

= 230 turns/min

second speed

= 315 turns/min

Excellence

made in Italy:

our mission

since 1949.

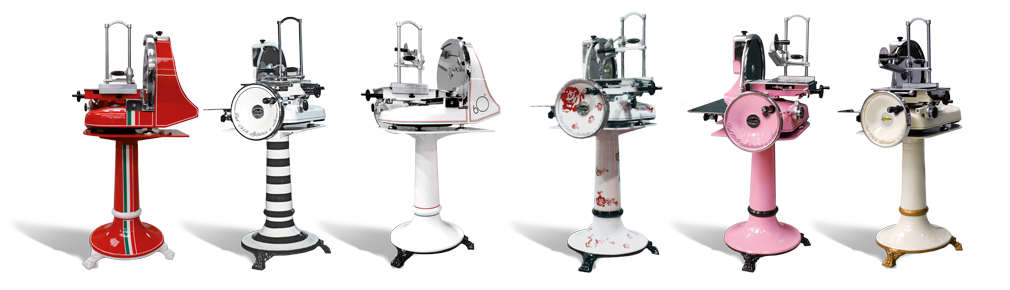

In 1949, Columbia slicing machines already had a very clear mission: to create a perfect machine to keep the Made in Italy flag flying high.

Based on a handmade production Columbia always gave precedence to quality over quantity, paying scrupulous attention to each small detail. Thus, the first collection of 6 hand operated slicing machines was produced addressed exclusively to the local market. Thanks to their excellent reliability and precision, the Columbia slicing machines met with immediate success! Even during the economic boom of the fifties, when the demand for slicing machines grew considerably further to the opening of numerous grocery shops, Columbia was not concerned about speeding up its production process as he was still firmly convinced that to produce something excellent, you must take all the time that is needed! This is how ours slicing machines came onto the home and international markets, with a solid image of top quality which permitted us to resist the constantly changing market and still be able to offer the best quality now available in the market.

Based on a handmade production Columbia always gave precedence to quality over quantity, paying scrupulous attention to each small detail. Thus, the first collection of 6 hand operated slicing machines was produced addressed exclusively to the local market. Thanks to their excellent reliability and precision, the Columbia slicing machines met with immediate success! Even during the economic boom of the fifties, when the demand for slicing machines grew considerably further to the opening of numerous grocery shops, Columbia was not concerned about speeding up its production process as he was still firmly convinced that to produce something excellent, you must take all the time that is needed! This is how ours slicing machines came onto the home and international markets, with a solid image of top quality which permitted us to resist the constantly changing market and still be able to offer the best quality now available in the market.

Columbia has today become a really future oriented brand, coming from the natural sixty years evolution.

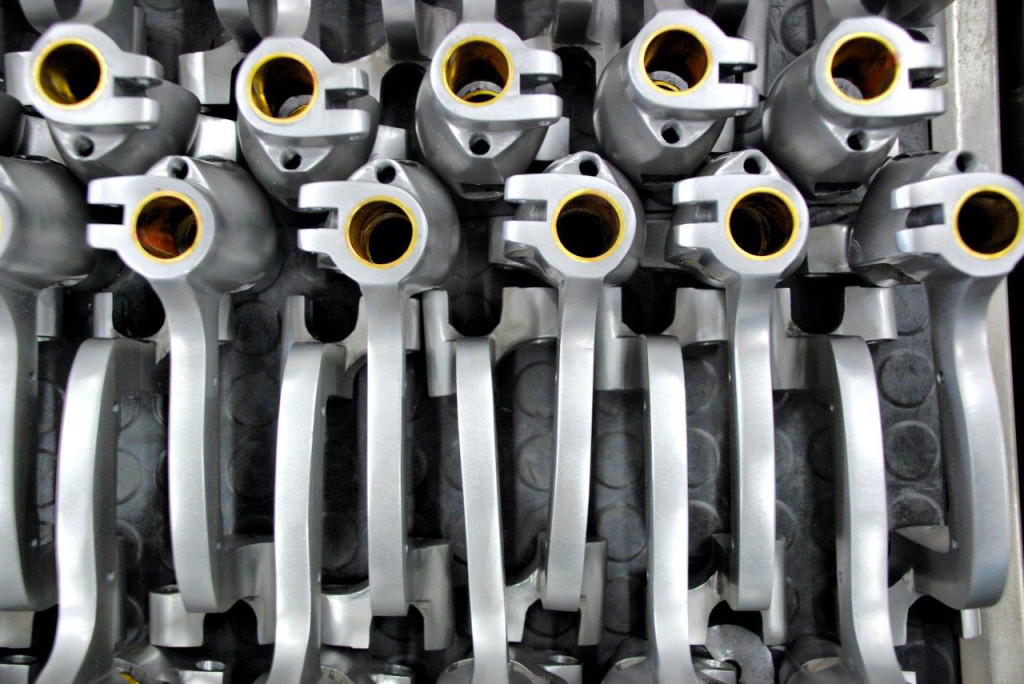

Although with the typical handicraft manufacturing qualities, where the “know-how” still lies in the ability of the craftsmen and their incomparable expertise, thanks to Gnodi Group Columbia has a commercial structure in order to be able to offer to its customers an even more efficient service. According to the most recent marketing theories, Columbia had developed a personalized customer-care service being aware that nowadays it is no more enough simply to manufacture a superior quality product but it is a must to support customers all along the supplying process. This means that our skilled technicians assist each of our customers from the beginning, with a valid consultancy to select the most suitable product for their specific needs, to the end, granting an assiduous presence for maintenance interventions.

The evolution of a tradition.

News

Contacts

Via dell’Industria, 2

21019, Somma Lombardo

Varese

21019, Somma Lombardo

Varese

Tel. +39 0331969260

Fax +39 0331969148

info@columbia-affettatrici.it

Fax +39 0331969148

info@columbia-affettatrici.it

gnodi service © 2015 •

Privacy policy •

Cookie policy